Technical ceramics materials (Alumina, Mullite, Silicon Carbide, Zirconia)

-

Overview

Our principal materials are:

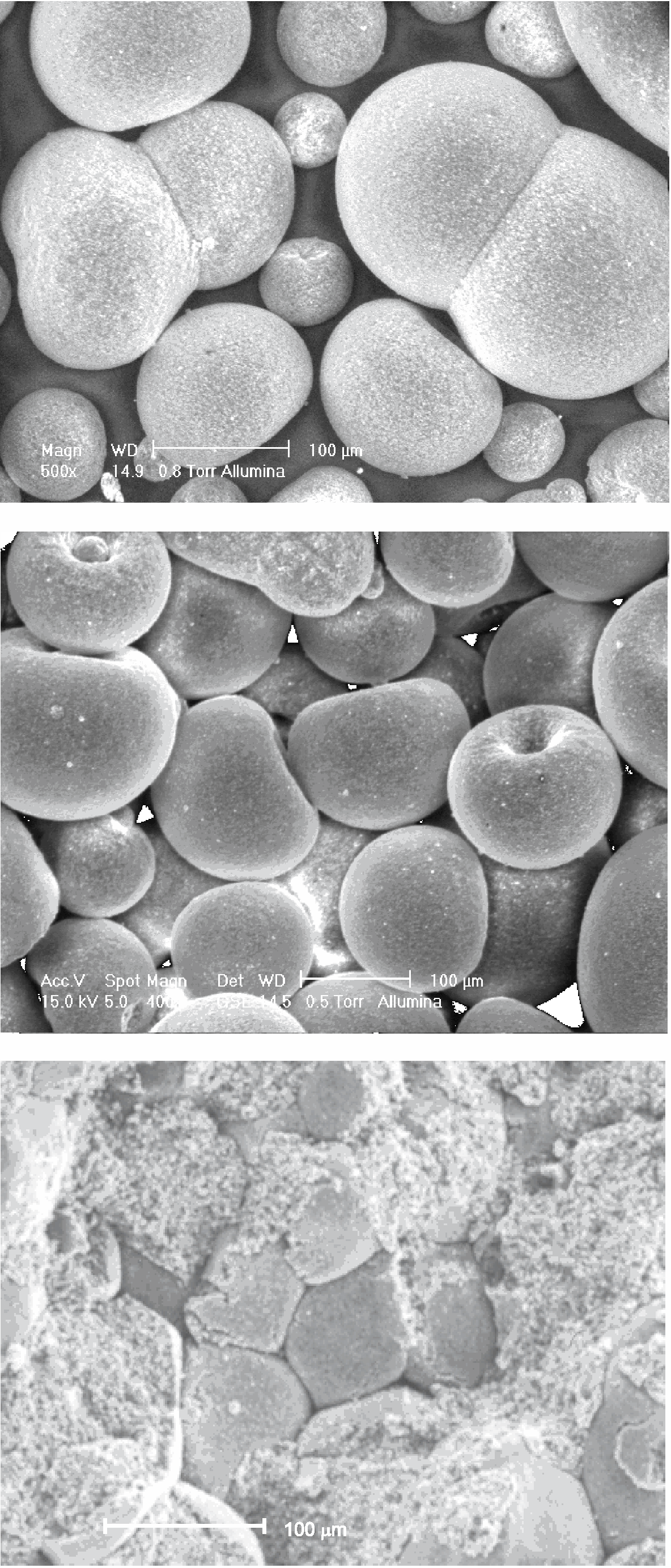

ALUMINA

Aluminium oxide (Al2O3) provides the basis for one of the most important technical oxide ceramic material groups. Alumina materials have established themselves as the material of choice for a wide range of applications as modern technologies demand improved performance in order to push products and processes to greater limits. Densely sintered alumina is characterised by:-

- high strength and hardness,

- temperature stability,

- Electrical insulation,

- high wear and friction resistance

- corrosion resistance even at high temperatures.

Industrial ceramic parts made from alumina oxide are usually composed of alumina with additions of other materials such as silica or magnesia. Alumina contents tend to range from 72% up to 99.99% alumina for some applications. Higher alumina contents are generally used where the application demands a higher performance in terms of temperature or wear capability.

A range of high purity alumina materials for use in high temperature, wear, corrosive or electrical insulation applications are available from Anderman Industrial Ceramics and its partner network. Stock is available in rods, tubes, thermocouple protection tubes, plates, crucibles, insulators.Special shapes also available on request according to specific and discreet customer demands.

- EA999 – Alumina 99.9% content

- EA998 – Alumina 99.8% content

- EA995 – Alumina 99.5% content

- EA96 – Alumina 96% content

- EA95 – Alumina 95% content

- EA99P – Alumina – 99% Porous

- EAZ20 – Zirconia Toughened Alumina

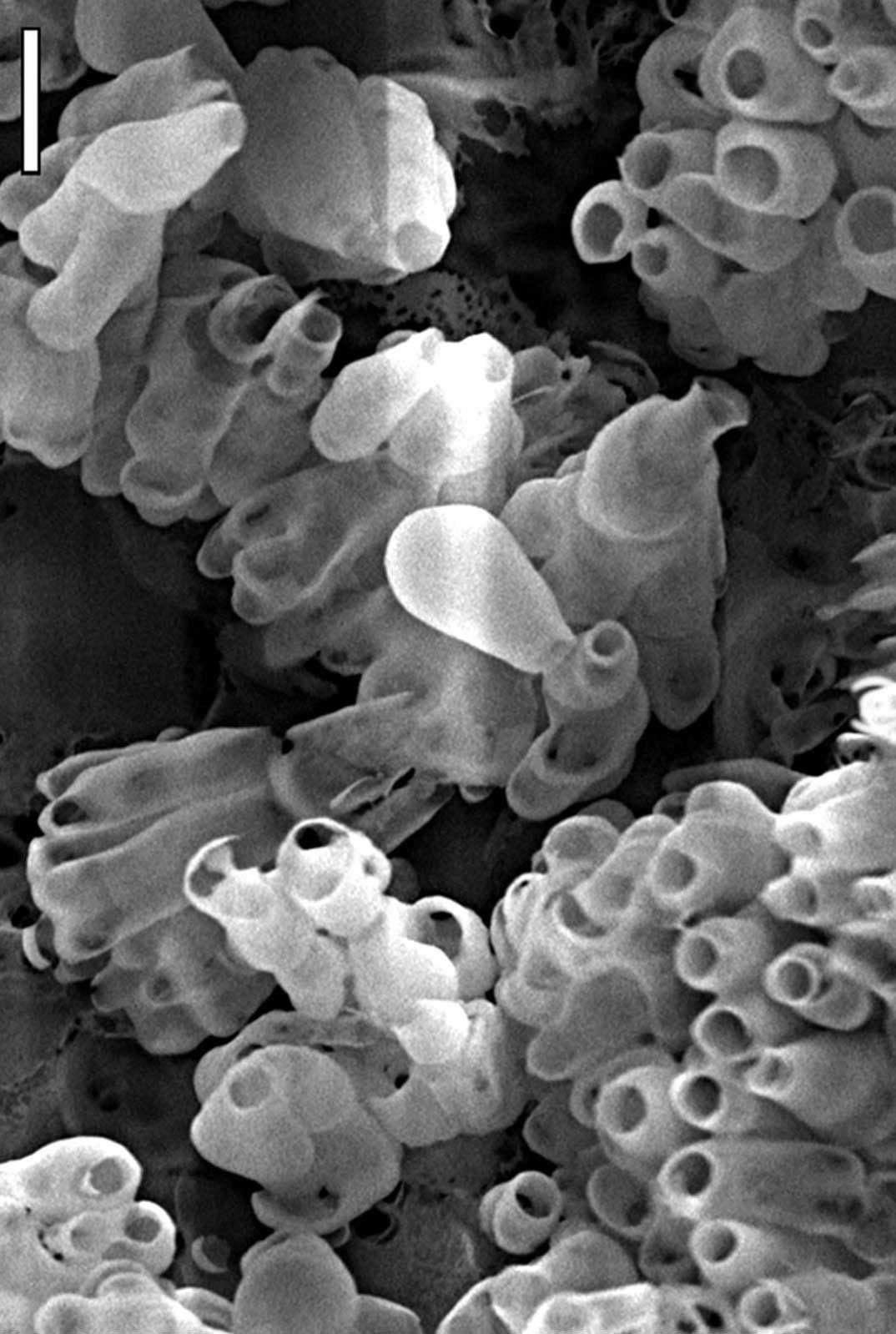

MULLITE

Mullite is a material that is manufactured by combining Alumina with Silica, fused together during sintering, in various combinations to produce a family of materials. Known as Mullite for the dense materials and Porous mullite or corundum for the porous grades.

Synthetic Mullite (Al2O3–SiO2) products are available in both impervious and porous forms. Densely sintered (impervious) mullite combines high strength with good thermal shock resistance. Porous mullite have a reasonably high strength combined with low thermal expansion giving improved levels of thermal shock.

Mullite ceramics with high thermal shock and operating temperatures up to 2910F (1600C) are used in furnaces, heaters, electrical insulation, wear and corrosion resistant applications. Stock is available in rods, Mullite tubes, insulators, thermocouple protection sheaths and crucibles.

These mullite materials are also available in Special and custom shapes according to specific and discreet customer demands.

- EM60 – Mullite – Impervious – 60% (min) alumina content

- EM60P – Mullite (sillimanite) – Porous – 60% alumina content

- EM80P – Corundum – Porous – 80% alumina content

TECHNICAL CERAMICS

In addition to the principal materials listed above we are also able to offer a number of special technical ceramic materials for a range of high temperature, wear and electrical resistance applications.

REQUEST A DATA SHEET ON MATERIALS BELOW

- Steatite

- Lava

- Quartz

- Forsterite

- Yttria

- Magnesia

Our range of ceramic materials is considerable and our experience enables us to source other, more specialist materials, upon request. We can deliver to most dimensional requests and also hold considerable stocks of standard shapes and sizes.

With our manufacturing partners we have over 100 years experience in ceramic forming technology utilising processes such as extrusion, slip casting, injection moulding, isostatic pressing and uniaxial pressing.

CLICK HERE FOR STANDARD PRODUCT LIST

QUARTZ

Quartz (Fused Quartz) as an industrial raw material is used to make various refractory shapes such as crucibles, trays, shrouds and rollers for several high temperature thermal processes including steelmaking, investment casting and glass manufacture. Refractory shapes made from Quartz have excellent thermal shock resistance and are chemically inert to most components and compounds including almost all acids, regardless of the application. Translucent fused silica (quartz) tubes are normally used to replace electric elements in room heaters, industrial furnaces and other similar applications. Quartz, in all its forms, offers a diversity of properties such as:

- Extreme Hardness

- Very Low Coefficient of Thermal Expansion

- Resistance to High Temperature

- High Chemical Purity

- High Corrosion Resistance

- Extensive Optical Transmission from Ultra-Violet to Infra-Red

- Excellent Electrical Insulation Qualities

- Remarkable Stability Under Atomic Bombardment

Our range of quartz products shows a very wide variety of possibilities, from small laboratory equipment to large wafer carriers or large diameter tubes.

SILICON CARBIDE

Porous silicon carbides with excellent thermal shock, high strength and high temperature operating capability up to 2910 F (1600C). Excellent for use in furnaces and molten metal applications due to it’s non wetting properties. Stock available in tubes, thermocouple sheaths, rods, crucibles and beams.

- EC70P – Silicon Carbide 70% (mullite bonded)

- EC90P – Silicon Carbide 90% (mullite bonded)

- EC100P – Recrystallised Silicon Carbide

ZIRCONIA

A range of zirconia materials either dense or with porosity. These materials offer high temperature capability upto 4370F (2400C) as well as excellent performance in areas of high wear and corrosion. Products are available as tubes, rods, Zirconia crucibles and a wide range of other shapes.

- EZY94 – Yttria partially stabilised

- EZY88 – Yttria fully stabilised

- EZM96 – Magnesia partially stabilised

- EZC96P – Calcia fully stabilised

- EZZ66P – Zircon

RARE EARTH MATERIALS

Rare earth refractory oxide ceramics exhibiting very high thermal stability, wear resistance and strength. Widely used in applications above 3090F (1700C), nuclear, high performance metal melting, oxygen sensors and semiconductor applications. Products are offered in a wide range of shapes including crucibles, ceramic tubes, laboratory furniture and thermocouple sheaths.

- EREY99 – Yttrium Oxide

- EREH99 – Hafnium Oxide – high purity

- EREH97Y – Hafnium Oxide stabilized with yttrium oxide

- EREC99 – Cerium Oxide

REFRACTORY MATERIALS

In addition to the principle materials listed above Anderman also offers a range of specialty refractory materials for high temperature applications.

REQUEST A DATA SHEET ON MATERIALS BELOW

- Cordierite

- Alumina Titanate

- Fused Silica

- Sillimanite

- Corundum

-

Alumina

-

Mullite

-

Zirconia

-

Refractories

- High Alumina

- Cordierite

- Sillimanite

- Corundum

-

Silicon Carbides

-

Other

- Quartz

- Forsterite

- Steatite

- Lava

- Yttria

- Magnesia